Limewash is a widely used traditional material known for its beautiful appearance and unique properties. Recently, It has gained popularity for its eco-friendly, breathable, and low-maintenance features. However, sometimes you may face an issue where your limewash rubs off or seems to deteriorate. Understanding the reasons behind this issue can help you address the problem effectively and maintain the aesthetic appeal of your surfaces.

The common reasons for limewash rubbing off are a bad application technique, poor quality limewash, and drying too quickly. It is essential to ensure that the surface is prepared correctly, with adequate moisture control and proper drying and carbonation processes. Another factor could be the lack of a mechanical key, in which case applying a shelter coat before reapplying the limewash can be beneficial.

Lastly, it’s essential to consider the environmental factors in your specific location, such as changes in temperature and humidity. This affects the performance of your limewash over time. By paying attention to these factors, you can find the right solution for the issue and ensure the longevity and beauty of your limewashed surfaces.

Understanding Limewash

Composition and Properties

Limewash is a natural, eco-friendly paint made from superfine lime putty, water, and natural pigments. Its high pH level makes it alkaline and creates an environment that is inhospitable to mould and bacteria, giving it anti-microbial properties. This breathable paint allows moisture to escape from the surface, reducing the risk of trapped moisture causing damage and rot to your walls.

Benefits and Drawbacks

Being natural and eco-friendly, limewash has several benefits:

- Anti-microbial: Thanks to its high alkaline content, limewash is resistant to mould, mildew, and bacterial growth.

- Breathable: It allows moisture to escape from the surface, reducing the risk of trapped moisture causing damage to your walls.

- Inexpensive: Limewash is generally less expensive compared to conventional paints.

- Aesthetics: It creates a beautiful, matte, textured finish that adds depth and character.

However, there are some drawbacks to consider as well:

- Rubbing off: Limewash can sometimes rub off if applied incorrectly or if the surface wasn’t properly prepared.

- Limitations: Using limewash with no additives limits its use to porous materials. It is possible to use natural additives such as casein to expand the range of surfaces limewash can be used on.

- Maintenance: Limewash used in exposed areas can require an extra coat or two every 3-7 years to keep it looking its best.

Related article: Limewash Pros and Cons: A Comprehensive Guide

Causes of Limewash Rubbing Off & Solutions

Incorrect Application

One of the main reasons for limewash rubbing off is improper application. When applying limewash to your masonry, plaster or render, it’s crucial to prime the surface by dampening it with water. Many surfaces are highly water-absorbent, like brick. When limewash is painted onto a surface that isn’t damp, the masonry will suck the moisture out of the limewash.

This will cause the limewash to dry without properly carbonating. Carbonation is the process in which the limewash absorbs carbon dioxide (CO2) out of the air in order to set. This only occurs while the limewash is still damp. If the limewash dries quickly, little to no carbonation can take place. This will cause the limewash to crack and craze. When fully dry, you’ll have a terrible powdery surface that will easily rub off.

Always ensure you are painting on a sufficiently damp surface. If you spray water onto the surface and it continues to be absorbed, keep going. You want the surface to be so damp that it cannot absorb any more water. However, it must not be running with water.

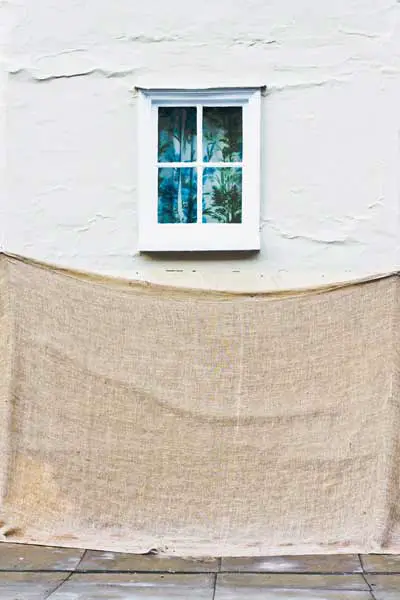

For limewash to achieve a good set, you should allow it to dry very slowly over 24 hours. If it’s drying too quickly, lightly mist-spray the limewash with water. Alternatively, you can hang damp sheeting in front of the limewash to slow drying. Hessian sheeting is best for this purpose.

Improper Mixing Before Use

Over time, limewash will settle. This is especially true if it’s a coloured limewash containing pigments or any other additives. You will often find a thick band of water sitting on top of the limewash. Do not tip this off. If your limewash is professionally prepared, it would have been made to the correct consistency. Therefore, you must thoroughly mix in the water with the limewash below.

The limewash must be whisked or otherwise mixed for a long time before use. Even the smallest clump of pigments will cause a very noticeable streak when brushed on. Ensure you regularly mix the limewash as you work. This will stop the suspended lime and pigments from sinking to the bottom, which is extremely important for an even finish.

Limewash should be the consistency of milk – which is much thinner than almost all other paints. If the limewash is thicker, first ensure it’s properly mixed; if it’s still too thick, add clean drinking water until it is the correct consistency.

External Factors

Various external factors can also contribute to limewash rubbing off. If applied on a hot, sunny day, the limewash may dry too quickly, causing poor adhesion to the surface. It’s best to apply limewash on an overcast day to allow it to dry slowly and evenly.

Another factor often overlooked is wind. Harsh winds can cause very quick drying. Drying winds must be protected against by using damp sheeting and, if possible, avoided altogether.

Rain can also cause the limewash to wash off if not given enough time to dry and cure. So, plan your limewashing project according to the weather forecast and avoid rainy days.

In conclusion, pay attention to proper preparation, application techniques, and external factors to prevent limewash from rubbing off. This way, you’ll enjoy a long-lasting and beautiful limewashed finish on your masonry or brick surfaces.

Related article: Is Limewash Better for Brick and Masonry Than Modern Paint?

Maintenance and Longevity of Limewash

When maintaining your limewashed surfaces, it’s essential to ensure their longevity for optimal appearance and protection against elements like wind and rain. Properly applying limewash to a suitable substrate and following specific guidelines can reduce the risk of it rubbing off on clothing or fading over time.

Reapplication and Touch-Ups

To maintain the appearance of your limewashed surface, reapplication might be necessary over time. Due to its nature, the limewash can fade as it is weathered over time, especially in areas exposed to harsh environmental conditions.

Observe the surface for any signs of fading or discolouration to determine when reapplication is needed. Reapplication of limewash is usually more affordable than traditional paint, making it an economical choice.

When touching up your limewashed surfaces, keep in mind several factors. First, ensure that the surface is dampened before applying new limewash, which promotes better adhesion. Secondly, using a brush specifically made for limewash application will ensure a more aesthetically pleasing and long-lasting result. Remember to allow for adequate drying time to reduce the risk of the limewash rubbing off.

Proper drying is a crucial factor in the maintenance and longevity of limewash. Adequate drying times may vary based on the substrate, but it’s essential not to rush this process. Ensure that the surface dries very slowly for at least 24 hours after application to achieve optimal results.

Proper maintenance of your limewashed surfaces involves regular reapplications (3-7 years), using the right tools like a limewash brush, allowing for sufficient drying time, and paying attention to factors such as weather and initial surface compatibility. By following these guidelines, you can enjoy the beautiful appearance of limewash on your surfaces for an extended period.

Related article: How Long Limewash Lasts & How Often it Should Be Reapplied

Key Takeaways

- Limewash is a natural, eco-friendly paint made from superfine lime putty, water, and natural pigments.

- Limewash has several benefits, such as being anti-microbial, breathable, inexpensive, and creating a beautiful, matte, textured finish that adds depth and character.

- The main reasons for limewash rubbing off are improper application, drying too quickly and poor quality limewash.

- Pay attention to proper preparation, application techniques, and external factors such as temperature and humidity to prevent limewash from rubbing off.

- Proper maintenance of limewashed surfaces involves regular reapplication and touch-ups, as well as protecting the surface from harsh environmental conditions.

- When cleaning the surface, use a soft-bristled brush or a damp cloth to avoid damaging the limewash, and avoid using harsh chemicals or pressure washers.

To prevent limewash from rubbing off, keep these tips in mind:

- Ensure proper surface preparation and follow manufacturer instructions for application.

- Allow adequate time for the limewash to carbonate (24 hours).

- Plan your application on a day without direct sunlight, drying winds or high temperatures.

- Monitor the area for potential causes of wear and address them promptly.